I have a small woodworking project I'm working on. It's the kind of thing that you can buy for a reasonable price and it'll be perfectly functional and attractive, but I've been very up front with this audience about my stubbornness in doing some things myself. At any rate, this is a good project for me and it will have a lot of sentimental value if I make it instead of buying it. But that project is not what this post is about.

We're at my parents' house this week, so I had to bring my workshop with me. For my project, I brought two boxes full of all-analog woodworking tools: dovetail saws, crosscut saw, tenon saw, bench chisels, mortise chisels, hand planes, marking gauges, dividers, the works. I figured I would find somewhere to set up a temporary workshop. Turns out my dad was telling their across-the-pasture neighbor that I was going to try to do this in their carport, and the neighbor extended the offer to use his workshop. It was a generous and helpful offer so I accepted. It happens to be extra special because the neighbor's house used to be my maternal grandparents' house, and the workshop is the very workshop where I spent many a childhood hour marveling at Papaw's skills as a woodworker, and where I learned my first lessons in the craft.

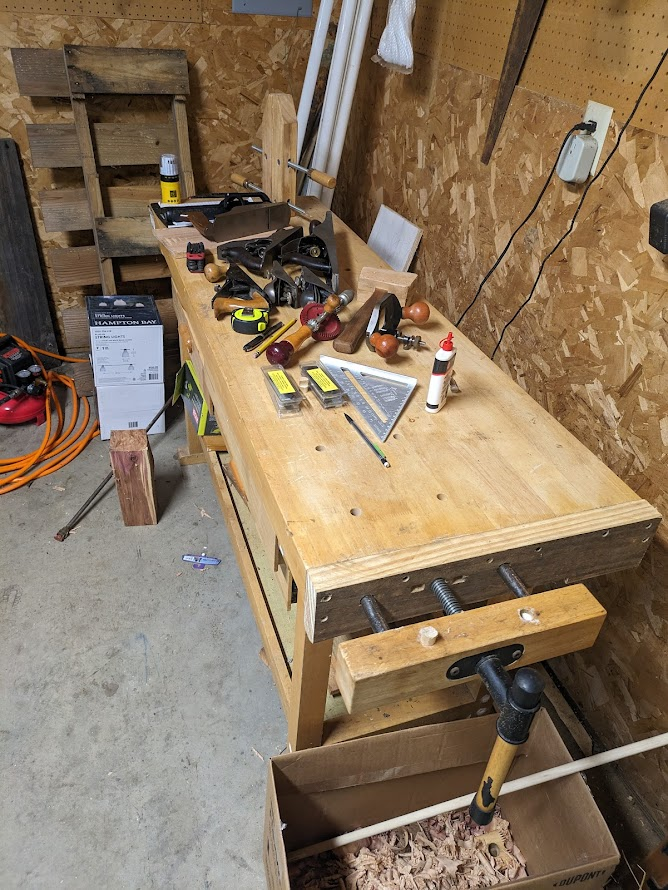

Even better still, this workshop has an actual cabinetry workbench. Now when I say "workbench," I don't just mean a table in the garage you don't mind scratching and banging on. In woodworking, a workbench must be sturdy, flat, level, and most importantly, it must have some method of holding the work firmly in place. There are several different ways of securing your work: bench hooks, holdfasts, crochets, battens, etc. But the most common work-holding apparatus you'll find in workshops worldwide is the vise. This workbench has what's called a "tail vise," which moves in and out at the end of the bench by turning a large threaded rod.

Let me take a moment here and acknowledge that I'm aware most of the eyes reading this are glazing over. If you're not into this, re-read the title of this post and you'll find that I'm as good as my word. But this stuff really is fascinating for a certain type of mind, and if you're one of the people who isn't bored by halfway-competent prose about old timey trades, you absolutely should read this book. I'm well aware that the woodworking minutiae is me really letting myself lean into the early-forties dad vibe and I've accepted it. Moving on.

The workbench available to me was most likely purchased as a kit and assembled on site. It's mass produced, but sturdy and flat. It wasn't made to be pretty, and the wood it was made from was cheap and functional finger-jointed stock. They sell similar benches at Harbor Freight and Northern Tool and the like. It's nothing flashy, and there are thousands upon thousands of nearly identical workbenches in garages of weekend wood warriors across the country. But it is sturdy, it is flat, it is level, and it has a mechanism to hold the work securely.

I brought some oak stock that I'm using for this project, and it actually was harvested from the big water oak that used to stand about 75 yards to the north of this workshop. That's not really pertinent to the post, but it is pretty neat. So I got some of that oak out and went to clamp the first board in the vise, itching to get my hand planes singing away on it. I turned the handle, tightening up the vise screw, and "CRACK!"

The benchtop's tail apron (the piece to which the tail vise is anchored) suddenly and catastrophically failed.

Nobody would have ever noticed before it broke, but one of the tail vise's anchoring screws just happened to be positioned right in the middle of the lumber's glued finger joints. In retrospect, it makes sense why it broke, but jeez, what are the odds of the screw going right through there. It's frustrating, especially when you've got big plans for getting some good work done on this project. For every one of these benches where the glue joint lines up just so with a screw hole, there are probably 200 where it's not a problem. Oh well, luck of the draw I guess. Though if I were standing in front of the manufacturer I would definitely complain about the quality control.

So there I was with a table. But I need more than a table, I need a workbench. This table was sturdy, flat, and level. But there was nothing there to grab hold of the workpieces. Nothing to keep the work secure and steady. A vise without something to anchor to can only hold one side of the work. Without a way to hold everything firmly and steadily, this was just a table.

But this project is important, and it's not one I'm willing to outsource. So I assessed my resources, and formed a plan. I did not have the type of wood I would prefer for this fix, so I used a scrap piece of construction lumber. I didn't have the right size drill bits for the threaded rod or the alignment pins, but I had a wide variety of other tools and some resourcefulness. I didn't have enough time to be dealing with this particular problem, but I have a project that needs to get done and I couldn't start working on it until I cobbled together a fix to get to the next step.

I used the broken piece as my guide, reverse-engineering how it was attached and how it worked to anchor the vise. I measured out the dimensions onto my scrap lumber and got to sawing, drilling, chiseling, squinting, test fitting, etc. And eventually, something functional emerged:

It wasn't (and isn't) pretty. It was an awkward fit because it wasn't the exact same dimensions as the original tail apron. It wasn't even the same species of wood as the rest of the bench. But I reinforced it as well as I knew how. I put decking screws in it everywhere I could possibly fit one. It was time to put a little force on it and see how it held up. If I'm being completely honest, I'm surprised at how well it worked. I still had to do a lot of resetting and fiddling, but eventually I got it to where it seemed to be holding the workpiece pretty well. And I finally got into a rhythm and by golly I made one flat piece of oak by the end of the day. This project is going to get finished.

Granted, this was not a high-end fix, and if this bench is to get used heavily in the future, it's likely a more elegant repair will be needed. But it's functional for now, and for the near future I think it's gonna hold.

Not too late for a second career in engineering. We get to wait for that finished product picture! Enjoyed this post!

ReplyDeleteWorking with wood is satisfying.

ReplyDeleteYou can come use Bill’s workshop anytime! Bisquick will gladly help 😊 love and hugs!

ReplyDeleteRoy Underhill would be proud. I've got his first book (long out of print), as well as some other tomes. I'll have to reread them now. Keep your chisel sharp, and your kerf true.

ReplyDeleteok, anonymous, I gotta know who I'm going to be talking with about Roy Underhill from now on.

DeleteWe are so impressed!!! Robert, you are a man with so many natural gifted talents. Can you post a picture of you and PaPa one day? Maybe a picture from Bakers Ferry Road. We loved Papa’s work room. That would be so special! What happy memories you shared with us! You really are a wonderful combination of 2 outstanding grandfathers! We love you, Clara and Eloise so very much! 🙏❤️Uncle Marvin and Aunt Pam

ReplyDelete06CECC85AB

ReplyDeletehacker bul

hacker bulma

tütün dünyası

hacker bul

hacker kirala